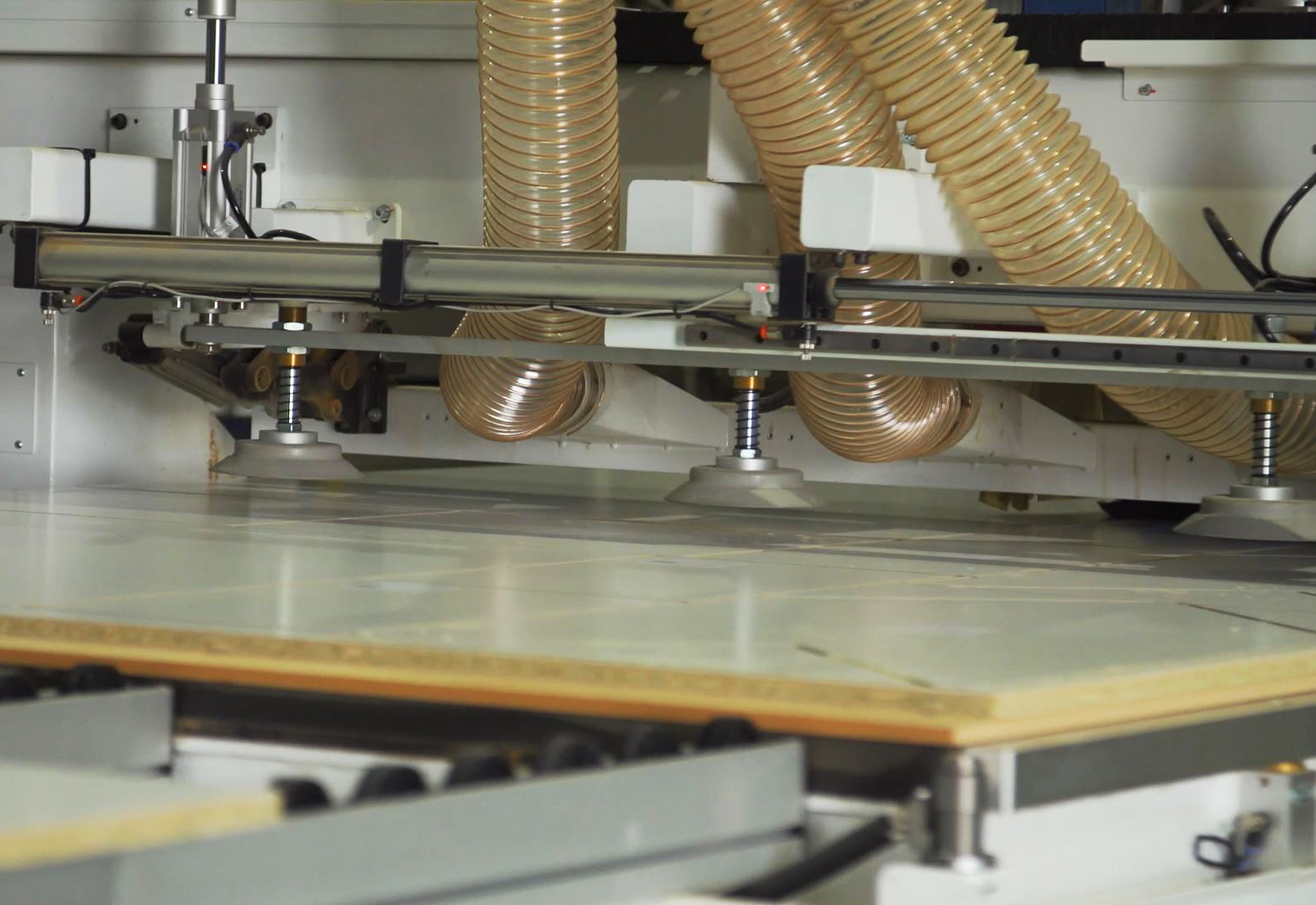

The Importance of Dust Extraction in the CNC Machining Process

In the world of cabinetry manufacturing, the CNC (Computer Numerical Control) machining process stands out as an indispensable tool for precision and efficiency. Yet, as with any industrial operation, the process creates byproducts, one of which is dust. The presence of dust not only poses operational challenges but also significant health and safety risks. As such, implementing an effective dust extraction system becomes crucial for cabinetry manufacturers that utilize CNC machines. Below, we explore the myriad reasons why dust extraction is a paramount concern.

1. Health and Safety Concerns

Dust, especially wood dust, can pose a severe health hazard to employees. Prolonged exposure can lead to respiratory conditions like asthma, chronic bronchitis, and even more severe conditions such as occupational asthma and lung cancer. By ensuring effective dust extraction, manufacturers can significantly reduce the exposure of their workers to these harmful particles, fostering a safer and healthier working environment.

2. Improved Product Quality

In cabinetry manufacturing, precision and attention to detail are paramount. Dust accumulation can interfere with the accuracy of CNC machines. Even minute quantities of dust can lead to inaccuracies in cutting or engraving, resulting in compromised product quality. An efficient dust extraction system ensures that the machine’s working area remains clear, allowing it to produce pieces with utmost accuracy consistently.

3. Enhanced Operational Efficiency

Dust accumulation can also lead to wear and tear on CNC machines. Fine particles can infiltrate the machine components, leading to quicker degradation of essential parts. By frequently cleaning and removing dust, manufacturers can extend the lifespan of their machinery, leading to less frequent downtimes and reduced maintenance costs.

4. Mitigation of Fire Risks

One of the most underappreciated risks associated with CNC machining, particularly in cabinetry manufacturing, is the potential for fire or even explosions resulting from the accumulation of wood dust. The danger that such accumulation poses cannot be overstated, with incidents reported where dust-fueled explosions have caused severe structural damage, including the complete blow-off of premises’ roofs. A deeper examination of this risk highlights the urgency for cabinetry manufacturers to prioritize efficient dust extraction systems.

Wood dust is highly combustible, especially when the particles are fine. These small particles have a large surface area compared to their volume, allowing them to ignite easily. In cabinetry manufacturing, vast quantities of this fine dust are produced, escalating the risk of ignition.

Explosions arise when there’s a perfect storm of the right conditions: an ignition source, oxygen, and a concentration of wood dust. If dust accumulates in an enclosed space (like a workshop or factory), a simple spark from a machine can ignite the airborne particles, causing a rapid combustion known as a deflagration. If this deflagration is contained within an enclosed area, the resulting increase in pressure can lead to a violent explosion, with the potential to blow off roofs or even demolish entire structures.

Several historical incidents underline the severity of this risk. There have been instances where unsuspecting facilities, believing they were following safety protocols, experienced catastrophic explosions due to seemingly minor oversights in dust management. These incidents have not only resulted in extensive property damage but have also jeopardized human lives, reinforcing the importance of proactive measures.

5. Environmental Responsibility

With the growing emphasis on sustainable manufacturing processes, industries are under scrutiny to ensure their operations cause minimal environmental impact. Efficient dust extraction systems can collect the majority of wood particles, allowing them to be recycled or disposed of responsibly. This not only reduces environmental impact but can also position a manufacturer as an industry leader in sustainable practices.

6. Cost Savings

In the long run, an effective dust extraction system can result in significant cost savings. By preventing machine wear and tear, reducing health risks, and mitigating potential fire hazards, manufacturers can avoid unexpected expenditures. Additionally, by ensuring consistent product quality, manufacturers reduce wastage due to defective pieces, further optimizing their operational costs.

7. Compliance with Regulations

Many regions have strict regulations in place for air quality standards within industries, especially those dealing with wood processing. Companies failing to adhere to these standards can face penalties or even operational shutdowns. Implementing an effective dust extraction system can ensure that manufacturers remain compliant, avoiding potential legal complications.

A Final Word

In conclusion, dust extraction in the CNC machining process goes beyond just maintaining a clean workspace. It touches upon critical aspects such as health and safety, operational efficiency, product quality, and environmental responsibility. For cabinetry manufacturers looking to optimize their operations, invest in their employees’ well-being, and ensure the longevity of their machinery, integrating a robust dust extraction system isn’t just advisable—it’s imperative.